Food Industry

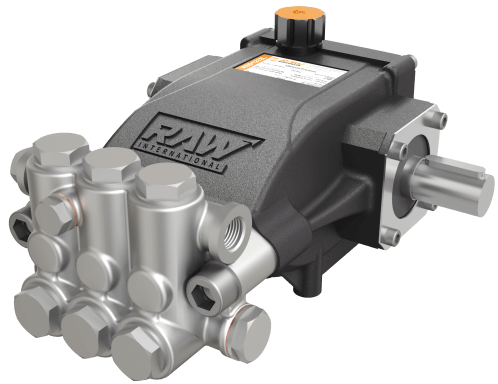

Revolutionizing the Food Industry with B K Gopala Plunger Pumps!

Plunger pumps play a vital role in the food industry, ensuring the cleanliness and hygiene of equipment, production areas, and processing machinery. These high-pressure pumps provide a reliable and efficient solution for a range of essential applications, helping to maintain food safety standards and product quality.

Sanitizing Processing Equipment: Plunger pumps are used to clean and sanitize food processing equipment, such as mixers, conveyors, and filling machines. High-pressure water or cleaning solutions remove residues, bacteria, and contaminants, ensuring the equipment remains sanitary and compliant with food safety regulations.

Cleaning Conveyor Belts: Food production lines often use conveyor belts to transport raw materials and finished products. Plunger pumps power high-pressure cleaning systems that effectively remove debris, crumbs, and potential allergens from conveyor belts, preventing cross-contamination.

Bottle and Container Washing: In beverage and packaging plants, plunger pumps are integral for cleaning bottles, containers, and packaging materials. They deliver high-pressure jets of water and sanitizing solutions to remove labels, dirt, and residues, preparing containers for reuse or recycling.

Decontaminating Surfaces: Plunger pump-driven cleaning systems are employed to sanitize production areas, floors, walls, and ceilings. They effectively eliminate bacteria, mold, and other contaminants, ensuring a clean and safe environment for food processing.

Cleaning Vats and Tanks: Food-grade tanks and vats must be thoroughly cleaned and sanitized between batches. Plunger pumps facilitate this process by delivering high-pressure water and cleaning solutions to remove product residues, ensuring tanks remain free from contamination.

Fruit and Vegetable Processing: Plunger pumps are utilized in fruit and vegetable processing to clean produce before packaging. They remove dirt, pesticides, and potential pathogens, contributing to the safety and quality of fresh produce.

Poultry Processing: Plunger pumps are crucial in poultry processing for cleaning and sterilizing equipment, slaughterhouses, and cutting rooms. They help eliminate pathogens, ensuring product safety.

Dough and Bakery Equipment: Plunger pump-driven systems clean bakery equipment, including dough mixers, ovens, and conveyors. Effective cleaning removes flour, dough residues, and contaminants, maintaining food quality and equipment longevity.

Cheese and Dairy Production: Plunger pumps are used in cheese and dairy production to clean milk tanks, pasteurizers, and cheese-making equipment. They ensure that dairy products are free from contaminants and safe for consumption.

Plunger pumps are indispensable tools in the food industry, contributing to food safety, product quality, and compliance with stringent regulations. Their high-pressure capabilities and precision enable efficient cleaning and sanitization of equipment, processing areas, and production machinery. By maintaining the highest standards of cleanliness and hygiene, plunger pumps play a crucial role in ensuring the safety and integrity of food products throughout the entire production process.