Construction

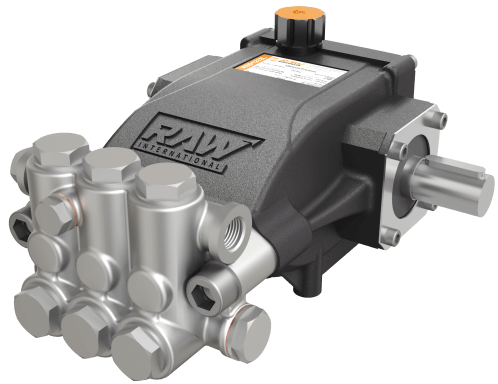

Revolutionizing the Construction Systems with B K Gopala Plunger Pumps!

Plunger pumps are widely used in the construction industry for various applications due to their ability to generate high-pressure water flow. Here are some common applications of plunger pumps in construction:

Concrete Pumping: Plunger pumps, often in the form of piston or reciprocating pumps, are used in concrete pumping systems. These pumps provide the necessary pressure to transport concrete from the mixer to the construction site, allowing for efficient placement of concrete in hard-to-reach areas, tall structures, or where traditional methods are impractical.

Hydrostatic Testing: Plunger pumps are employed in hydrostatic testing of pipelines, tanks, and other structural components to check for leaks, defects, or structural integrity. High-pressure water is pumped into the system to simulate operating conditions and ensure that it can withstand the required pressure without failure.

Surface Preparation: Plunger pumps are used for surface preparation tasks such as cleaning, roughening, or removing coatings from concrete, steel, and other construction materials. High-pressure water jetting systems powered by plunger pumps efficiently remove dirt, rust, paint, and other contaminants, providing a clean and prepared surface for subsequent construction work or coatings.

Pipe and Drain Cleaning: Plunger pumps are utilized for cleaning drains, sewers, and pipelines in construction projects. High-pressure water jetting powered by plunger pumps effectively removes debris, roots, scale, and other obstructions from pipes, restoring flow capacity and preventing blockages.

Dust Suppression: Plunger pumps are used for dust suppression on construction sites to control airborne dust particles generated during activities such as demolition, excavation, and material handling. High-pressure water jets generated by plunger pumps can dampen the dust and reduce its dispersion, improving air quality and safety for workers.

Soil Stabilization: Plunger pumps are employed in soil stabilization processes, where high-pressure water jets are used to inject grout or other stabilizing agents into the soil to improve its load-bearing capacity, control erosion, or mitigate ground settlement issues in construction projects.

Plunger pumps are essential tools in the construction industry, facilitating tasks such as concrete pumping, hydrodemolition, surface preparation, and dust suppression. Their ability to generate high-pressure water flow enables efficient and precise operations, contributing to the success and safety of construction projects.