Chemical Industry

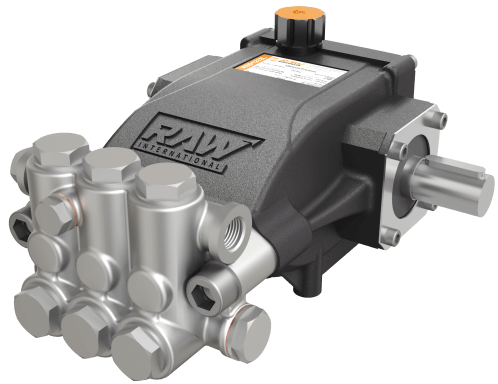

Revolutionizing the Chemical Industry with B K Gopala Plunger Pumps!

The chemical industry is a diverse and critical sector that involves the production, processing, and transportation of various chemicals and compounds. Plunger pumps have found wide-ranging applications in this industry due to their ability to handle aggressive and corrosive fluids, precise flow control, and high-pressure capabilities. They play a pivotal role in ensuring the efficient and safe handling of chemicals throughout the production process.

Chemical Metering and Dosing: Plunger pumps are used for accurate chemical metering and dosing in chemical processing. They precisely inject chemicals into reactors, mixers, and pipelines, ensuring the correct chemical composition for reactions and product formulations.

Chemical Transfer and Loading: Plunger pumps facilitate the safe and efficient transfer of chemicals from storage tanks to processing equipment or transportation containers. Their ability to handle a wide range of viscosities and corrosive substances is essential for maintaining product integrity.

Pumping Aggressive Chemicals: Plunger pumps are employed to pump aggressive and corrosive chemicals, including acids, bases, and solvents. Their robust construction and resistance to chemical attack make them ideal for handling these challenging fluids.

High-Pressure Cleaning: Plunger pumps are used in cleaning processes within the chemical industry. They deliver high-pressure water or cleaning solutions for the cleaning of equipment, reactors, and storage tanks, ensuring the removal of contaminants and residues.

Cooling Systems: Plunger pumps play a role in cooling systems for chemical processes and equipment. They circulate cooling fluids, maintaining optimal temperatures to prevent overheating and maintain process efficiency.

Reactor Feed Systems: Plunger pumps are employed in reactor feed systems to maintain precise pressure and flow rates of reactants into chemical reactors. This ensures controlled reactions and prevents accidents or inconsistencies in product quality.

Chemical Filtration: Plunger pumps are used to pressurize filtration systems that separate solids from chemical solutions. This process is crucial for purifying chemicals and achieving desired product specifications.

Water Treatment: Plunger pumps are used in water treatment processes within the chemical industry. They deliver chemicals for coagulation, flocculation, pH adjustment, and disinfection, ensuring the purification of water used in production processes.

Chemical Packaging: Plunger pumps facilitate the precise filling and packaging of chemical products into containers, ensuring accurate dosing and preventing product waste.

Plunger pumps are versatile and reliable devices extensively utilized in the chemical industry for a wide range of applications. Their ability to handle high pressures, precise metering, and resistance to corrosive substances make them indispensable in various chemical processes. From chemical injection and transfer to hydrocarbon processing and water treatment, plunger pumps contribute to the efficient and safe operation of chemical plants, enhancing productivity and ensuring consistent product quality.