Introduction

Hydrostatic testing stands as a cornerstone procedure in various industries, ensuring the structural integrity and leak-tightness of critical components. At the heart of this process lies the pressure pump, a vital tool that enables the generation and control of high-pressure fluids essential for conducting hydrostatic tests. In this article, we delve into the indispensable role of pressure pumps in hydro test applications, highlighting their significance, functionalities, and the impact they have across different sectors.

Understanding Hydrostatic Testing

Before diving into the role of pressure pumps, let’s grasp the essence of hydrostatic testing. This method involves subjecting a vessel, pipeline, or component to fluid pressure higher than its operating pressure to assess its strength, integrity, and ability to contain the intended fluid without leakage. Water is commonly used due to its incompressibility and availability, though other fluids may be utilized depending on specific requirements.

The Crucial Role of Pressure Pumps

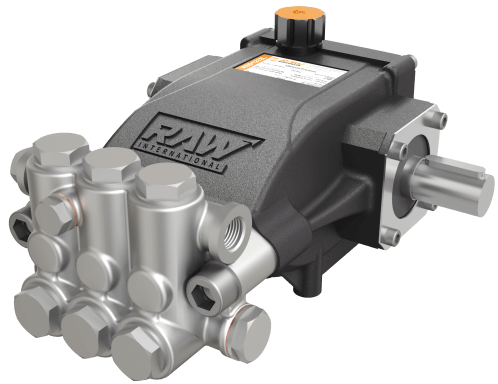

Pressure pumps, particularly plunger pumps, serve as the backbone of hydrostatic testing. Here’s how they contribute significantly to the process:

1. High-Pressure Generation

Pressure pumps are adept at generating the high pressures required for hydrostatic testing, ranging from hundreds to thousands of pounds per square inch (psi). This capability ensures that components are subjected to the necessary stress levels to detect any weaknesses or flaws accurately.

2. Precise Pressure Control

Control overpressure levels is paramount in hydrostatic testing to maintain accuracy and safety. Pressure pumps are equipped with mechanisms for precise pressure regulation, such as relief valves and variable frequency drives. These features allow operators to adjust and maintain pressure within tight tolerances throughout the testing procedure.

3. Consistent Flow Rates

Pressure pumps deliver a consistent flow rate, ensuring uniform pressurization of the test subject. This consistency is crucial for obtaining reliable test results and detecting any leaks or abnormalities in the component being tested.

4. Portability and Versatility

Pressure pumps come in various sizes and configurations, including portable models suitable for on-site testing applications. Their portability and versatility make them indispensable for testing pipelines, pressure vessels, and newly installed equipment across different locations and industries.

5. Safety Features

Safety remains a paramount concern during hydrostatic testing. Pressure pumps are equipped with built-in safety features, such as pressure relief valves and pressure monitoring systems, to prevent over-pressurization and ensure operator safety throughout the testing process.

Conclusion

In conclusion, pressure pumps play a pivotal role in hydrostatic testing applications, facilitating the generation, control, and regulation of high-pressure fluids essential for evaluating the integrity of critical components. Their reliability, precision, and safety features make them indispensable tools across various industries, ensuring the continued safety and efficiency of industrial infrastructure and equipment. As technology advances, pressure pumps continue to evolve, further enhancing their capabilities and expanding their applications in hydrostatic testing and beyond.